Advantages of a Closed-Loop System in Pulp Thermoforming Technology

Pulp thermoforming is a sustainable manufacturing method that becomes even more environmentally

efficient when integrated into a closed-loop production system. This approach offers multiple benefits

by minimizing waste, conserving resources, and reducing environmental impact.

TECHNOLOGY – ADVANTAGES

Biodegradability

Our pulp-based products

naturally decompose and

are suitable for composting ensuring they break down without leaving lasting residues in the environ-ment. This ecofriendly production method contributes to preserving nature.

Recyclability

Pulp items are fully

recyclable, allowing them

to be reused and repur-posed without generating waste.

Sustainability

We follow circular economy principles – minimizing environmental impact

while maintaining production efficiency through the use of renewable resources.

Economy

Pulp thermoforming is a

cost-effective technology

that offers practical and

sustainable manufacturing

solutions.

WATER RECIRCULATION

One of the key features of the closed-loop system is the continuous reuse of water throughout the production process.

• Water used in the pulping and forming stages is collected, filtered, and returned to the system.

• This reduces overall water consumption and minimizes wastewater discharge.

• It also lowers operational costs and supports compliance with environmental regulations.

RAW MATERIAL LOOP

In a closed-loop setup, every production scrap becomes a resource for the next cycle.

• Trimmings, offcuts, and defective items are re-pulped and reintegrated into the raw material stream.

• This eliminates the need for external waste disposal and reduces the demand for virgin materials.

• It ensures maximum material efficiency and supports circular economy principles.

OVERALL BENEFITS

• Waste Reduction: Virtually no production waste is sent to landfill.

• Resource Efficiency: Water and fiber are used multiple times without compromising product quality.

• Cost Savings: Lower consumption of fresh materials and reduced waste management expenses.

• Environmental Impact: Significant reduction in carbon footprint and natural resource depletion.

QUALITY

At Pulp Solutions Poland, we place the highest value on quality. Every item we produce undergoes thorough inspection – both during

manufacturing and within our specialized quality assurance team, to ensure it meets strict performance and environmental standards. From sourcing raw materials to the final stages of packaging, each step is closely supervised to uphold durability, usability, and

eco-consciousness.

Our pursuit of excellence is backed by globally respected certifications. We proudly hold the FSC® (Forest Stewardship Council) certification, confirming that our materials originate from forests managed with care and responsibility. We also maintain ISO 9001 certification, a testament to our robust quality management system and our ongoing efforts to improve and exceed customer expectations.

By integrating meticulous quality oversight with environmentally responsible methods, Pulp Solutions Poland offers packaging solutions that are both dependable and sustainable. Customers can rely on us for products crafted with care, precision, and a deep commitment to ethical production.

SERVICE AND MAINTANANCE

Pulp Solutions Poland maintains smooth and efficient production thanks to its specialized maintenance team and on-site tooling workshop. Our skilled professionals oversee the upkeep, adjustment, and repair of equipment, ensuring continuous operation and peak

performance. By managing tooling processes internally, we significantly cut down on delays, lower operational expenses, and enhance

the longevity of our machinery.

This proactive strategy enables us to uphold exceptional quality while delivering dependable and economically sound manufacturing.

It’s a reflection of our dedication to both excellence and environmentally responsible practices.

-

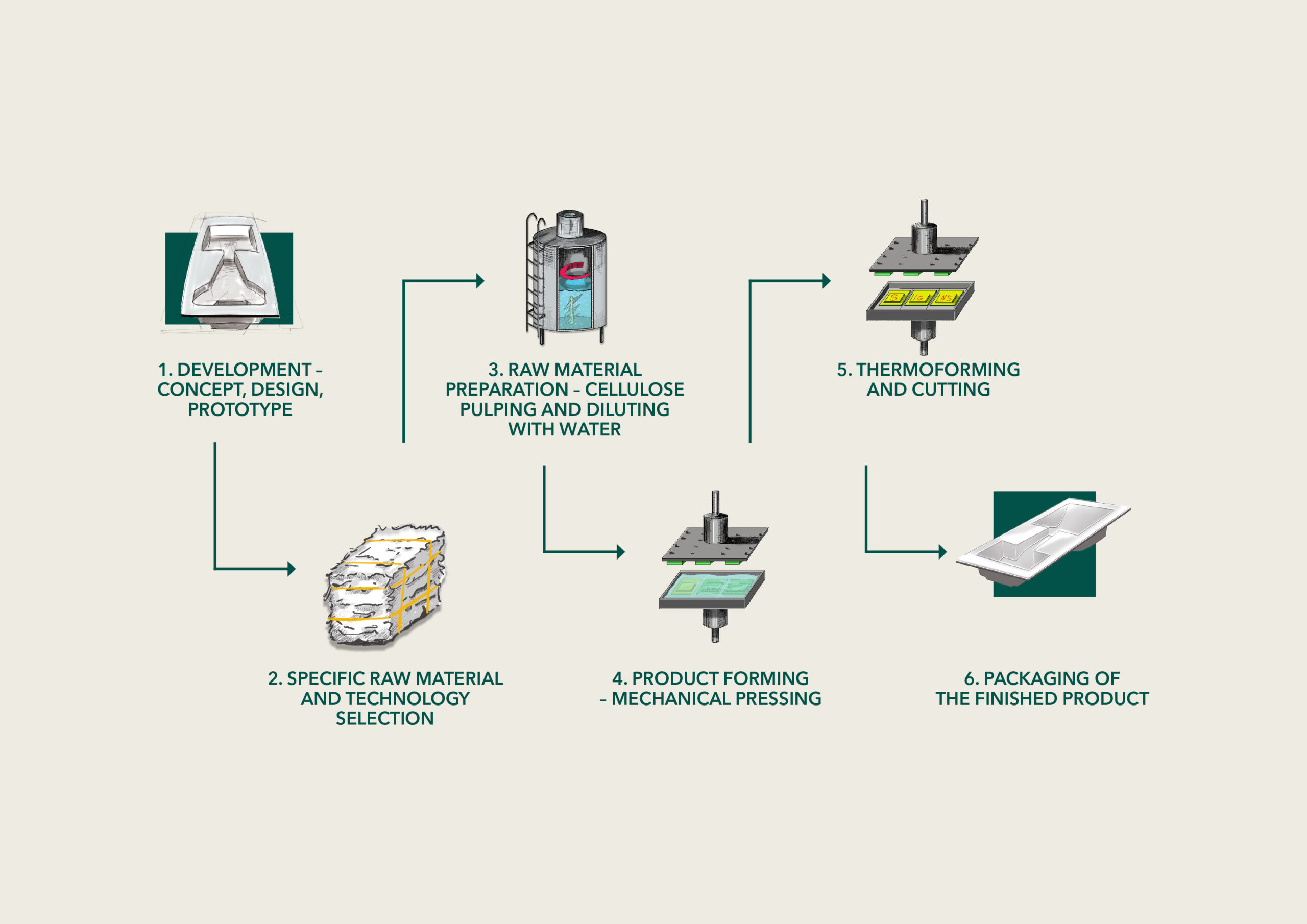

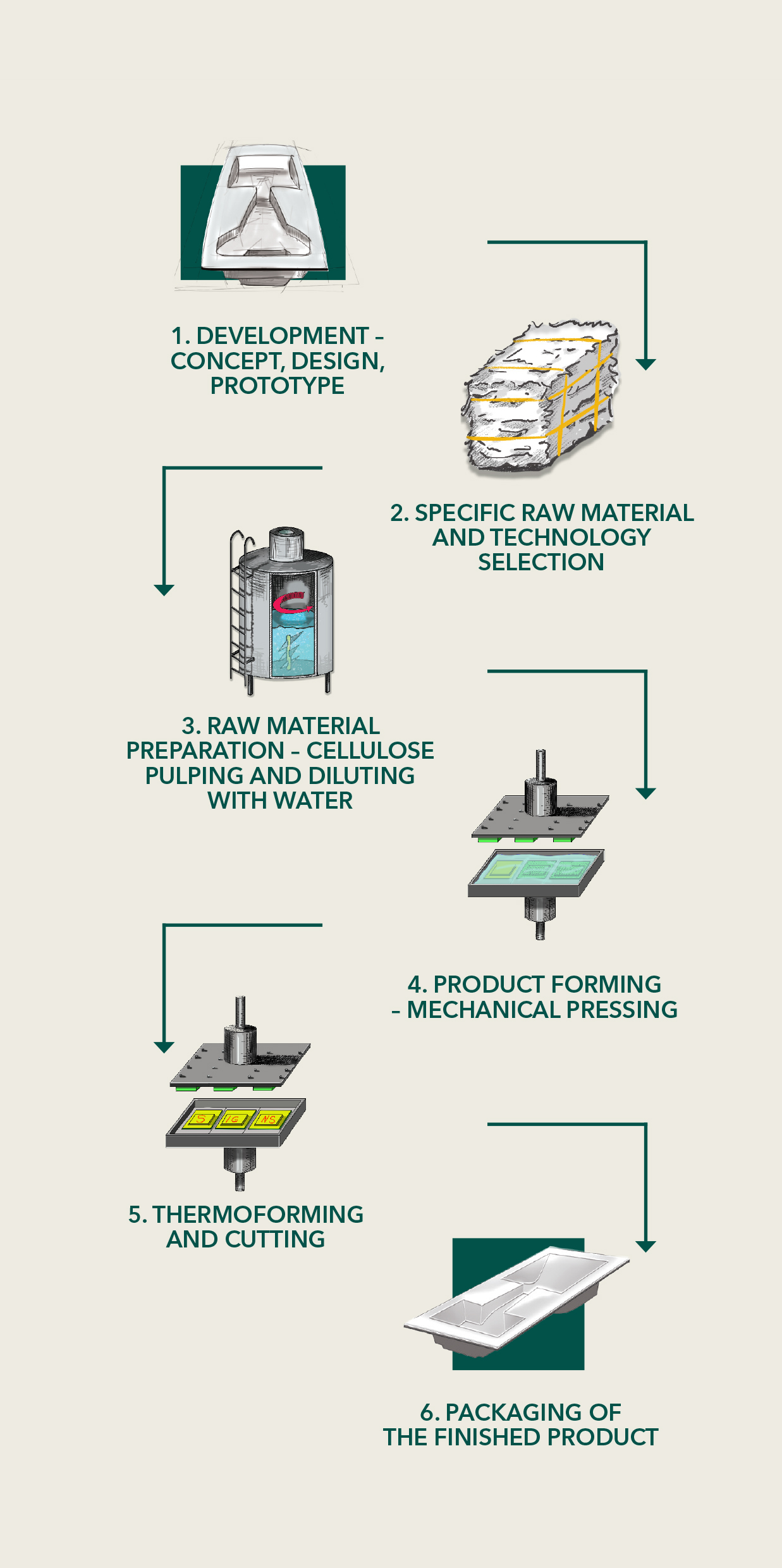

Development – Concept, Design, Prototype

This initial phase involves defining the product’s purpose, functionality, and environmental goals. Designers create detailed sketches and 3D models, followed by prototype development to test form, fit, and performance. This stage ensures the product meets both technical and sustainability standards before moving to full-scale production.

-

Specific Raw Material and Technology Selection

Careful selection of raw materials, typically recycled paper or natural fibres, is crucial. The company evaluates the environmental impact, availability, and compatibility with production technologies. Simultaneously, the most efficient and eco-friendly manufacturing methods are chosen to align with circular economy principles.

-

Raw Material Preparation – Cellulose Pulping and Diluting with Water

The selected materials are broken down into cellulose fibers through pulping. This pulp is then mixed with water to create a slurry with the right consistency for molding. The process ensures uniform fiber distribution, which is essential for product strength and quality.

-

Product Forming – Mechanical Pressing

The diluted pulp is poured into molds and mechanically pressed to remove excess water and shape the product. This step defines the product’s structure and surface texture. Precision in pressing ensures dimensional stability and reduces material waste.

-

Thermoforming and Cutting

Once formed, the product undergoes thermoforming—where heat is applied to harden and finalize its shape. After curing, the item is trimmed and cut to exact specifications. This stage enhances durability and prepares the product for final use.

-

Packaging of the Finished Product

The final products are inspected for quality, then packaged using sustainable materials. Packaging is designed to protect the items during transport while minimizing environmental impact. Labels and documentation may also highlight the product’s eco-friendly lifecycle.

RECENT NEWS

Visit our blog to discover expert insights on sustainable packaging, circular

economy strategies and the innovations shaping a greener future.